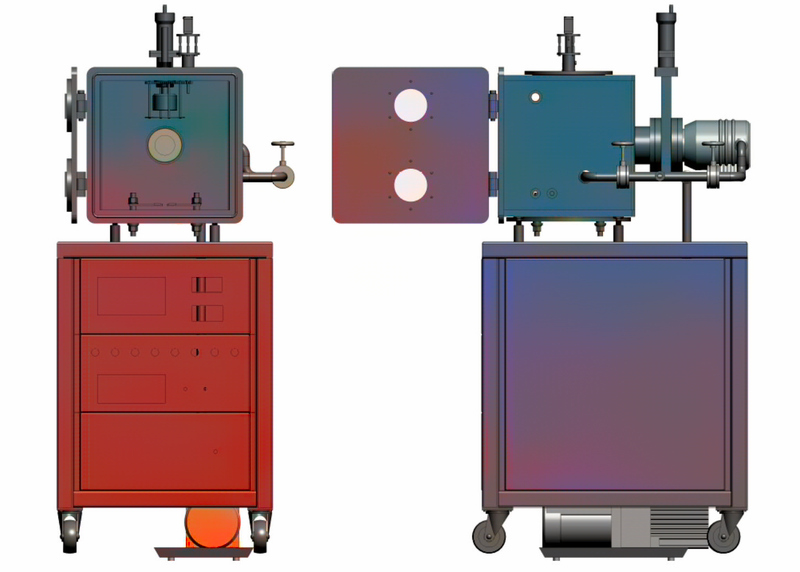

THERMAL EVAPORATOR SYSTEM

Thermal Evaporator Systems

At VEC Solutions, we offer top-of-the-line Thermal Evaporator Systems designed to meet the precise requirements of modern laboratories and industrial applications. Our systems provide reliable, efficient, and high-quality thin film deposition, essential for advanced material research, electronics, optics, and more.

Key Features and Benefits

Superior Deposition Quality

Our Thermal Evaporator Systems are engineered to deliver exceptional film uniformity and purity. With advanced thermal management and precise control over deposition parameters, you can achieve high-quality thin films that meet the strictest standards.

Versatile Applications

Designed for versatility, our thermal evaporators can handle a wide range of materials, including metals, insulators, and semiconductors. This makes them suitable for various applications such as microelectronics, photovoltaic cells, optical coatings, and nanotechnology research.

Precision Control

Equipped with state-of-the-art control systems, our thermal evaporators offer precise management of temperature, deposition rate, and film thickness. This ensures reproducibility and accuracy in every deposition process, essential for high-end research and production.

Robust Design

Built with durability in mind, our Thermal Evaporator Systems feature high-quality materials and robust construction. This ensures long-term reliability and minimal maintenance, even under demanding operating conditions.

User-Friendly Interface

Our systems come with an intuitive user interface, making them easy to operate and program. This allows users to quickly set up and execute complex deposition processes with ease, enhancing productivity and efficiency.

Pump Options

To cater to diverse operational requirements, we offer two types of pump-based Thermal Evaporator Systems:

Turbo Pump Based Thermal Evaporators

Our turbo pump-based systems provide rapid pump-down times and achieve high vacuum levels, ideal for applications requiring ultra-clean environments and high deposition rates. These systems are perfect for producing high-purity thin films and for use in high-vacuum applications.

Diffusion Pump (DP) Based Thermal Evaporators

Our diffusion pump-based systems are cost-effective solutions for achieving high vacuum levels suitable for many thin film deposition applications. These systems are known for their robustness and reliability, making them an excellent choice for general-purpose thermal evaporation processes.

Applications

Our Thermal Evaporator Systems are ideal for a variety of applications, including:

• Microelectronics: Deposition of thin metal layers for integrated circuits and semiconductor devices.

• Optical Coatings: Production of anti-reflective coatings, mirrors, and other optical components.

• Nanotechnology: Fabrication of nanostructures and thin films for advanced research

• Photovoltaics: Development of thin-film solar cells and other photovoltaic devices.

• Material Science: Study of material properties and development of new materials.

Why Choose VEC Solutions?

• Expertise and Innovation:With years of experience and a commitment to innovation, we provide cutting-edge solutions that meet the evolving needs of our customers.

• Customization: We offer tailored solutions to fit your specific requirements, ensuring optimal performance for your applications.

• Comprehensive Support: From initial consultation to installation and ongoing maintenance, our dedicated support team is here to assist you at every step.

Enhance your research and production capabilities with our high-performance Thermal Evaporator Systems. Contact us today to learn more about our products and how they can benefit your laboratory or industrial processes.